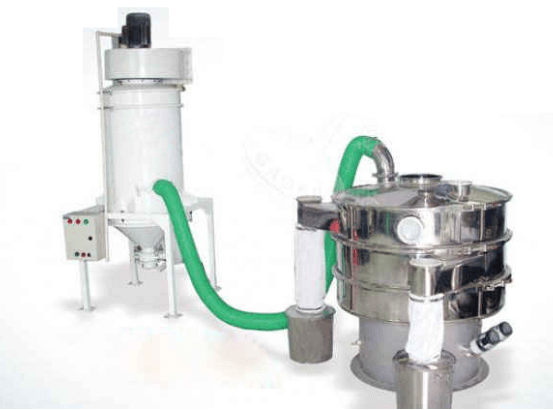

Industrial Sieving Machines: Enhancing Efficiency and Product Quality

Industrial sieving machines play a pivotal role in processing across various industries, helping companies maintain product quality, improve efficiency, and achieve regulatory compliance. These machines, also known as separators or screeners, are integral in filtering out impurities, segregating materials by particle size, and optimizing production lines. In industries ranging from food and pharmaceuticals to chemicals and minerals, sieving machines are an invaluable asset for maintaining consistency and quality.

Industrial sieving machines are robust equipment designed to separate materials based on particle size through a screen or mesh. These machines help isolate impurities or segregate materials for further processing. They come in different types, with variations in mesh size, vibration frequency, and sorting mechanisms, each suited for specific industrial applications.

Sieving machines are commonly used in:

- Pharmaceuticals: To ensure products are free from contaminants.

- Food & Beverage: For sifting flour, sugar, spices, and other ingredients.

- Chemicals: To separate powders, granules, and other substances.

- Mining & Minerals: For sorting crushed stones, sands, and ores.

Types of Industrial Sieving Machines

Choosing the right sieving machine depends on the material being processed, required output, and environmental conditions. Here are some common types:

- Vibrating Sifters: Equipped with a vibrating mechanism, these machines use rapid back-and-forth motions to filter materials efficiently. They are suitable for fine powders and high-precision sorting.

- Rotary Sifters: These employ rotating cylindrical screens to process materials, making them ideal for large-volume operations. Their rotary motion is gentle on fragile materials, making them suitable for delicate substances in food and pharmaceuticals.

- Centrifugal Sifters: Using centrifugal force, these machines push materials through the screen, effectively separating finer particles. These are well-suited for fine powders and substances requiring high cleanliness.

- Ultrasonic Sieving Machines: Designed for ultrafine separation, ultrasonic sieves use sound waves to prevent screen clogging, which is beneficial when dealing with highly cohesive or sticky powders.

See also: Enhancing Digital Wallet Security with Advanced AI Encryption Techniques

Benefits of Industrial Sieving Machines

Industrial sieving machines provide a host of benefits to companies aiming for high-quality standards and efficient production.

- Product Consistency: Sieving machines ensure particle size consistency, which is critical in industries like pharmaceuticals and food, where consistency affects both safety and quality.

- Contamination Prevention: Sieves act as a barrier to impurities and contaminants, making them essential in regulated industries such as healthcare and food.

- Increased Efficiency: Automated sieving machines reduce manual labor, enabling faster processing rates, reducing human error, and increasing production efficiency.

- Cost Savings: By reducing waste, enhancing efficiency, and increasing throughput, sieving machines help companies cut costs associated with re-processing and waste disposal.

Key Features to Consider in an Industrial Sieving Machine

When selecting a sieving machine, it’s essential to assess specific features to ensure it meets production requirements:

- Mesh Size and Compatibility: The mesh size must match the particle size requirements, with some machines offering adjustable mesh screens for flexibility.

- Capacity and Throughput: Machines vary in their throughput capabilities, so it’s crucial to select one that aligns with production demands to avoid bottlenecks.

- Durability and Material: Industrial sieving machines are often made from stainless steel to resist corrosion and withstand intense usage. Consider materials that offer long-term durability and ease of cleaning.

- Vibration Control: Machines with effective vibration control systems minimize wear and tear, reduce noise levels, and enhance precision in sieving.

- Hygienic Design: For industries like food and pharmaceuticals, machines must be easy to clean, with designs that minimize dust accumulation and contamination.

Applications Across Industries

Let’s take a closer look at how different industries leverage sieving machines:

- Food Industry: Sieving machines are widely used in food processing to sift flour, sugar, spices, and other powdered ingredients, ensuring purity and consistency in texture. They are also utilized to remove contaminants, like metal shavings or packaging residues.

- Pharmaceutical Industry: In pharmaceuticals, the consistency and cleanliness of ingredients are crucial. Sieving machines help separate fine powders, removing impurities and ensuring that each batch adheres to strict regulatory standards.

- Chemical Industry: Sieving machines help sort and classify various chemicals based on particle size, which is essential for controlled reactions and precise formulations.

- Mining and Minerals: The mining industry uses sieving machines to separate rocks, ores, and sands, enabling more efficient extraction and refinement processes. Here, the robustness of the sieving machine is paramount due to the abrasive nature of the materials.

How to Maintain Industrial Sieving Machines

Regular maintenance is vital to ensure the longevity and efficiency of sieving machines. Here are some maintenance practices to follow:

- Regular Cleaning: Frequent cleaning prevents material build-up and contamination, especially in food and pharmaceutical applications.

- Screen Replacement: Over time, mesh screens can wear out or become clogged. Replacing screens regularly keeps the machine running smoothly.

- Lubrication of Moving Parts: Lubrication reduces friction, minimizes wear on components, and prolongs the machine’s lifespan.

- Inspection of Vibratory Motors: The motors driving vibratory sifters require periodic inspection to ensure consistent performance and prevent breakdowns.

- Calibration and Testing: Regular calibration and performance testing are essential, especially in industries where product consistency is critical.

Innovations in Industrial Sieving Technology

With advancements in technology, industrial sieving machines are becoming more efficient, customizable, and adaptable. Here are some recent innovations:

- Automated Sieving Solutions: Modern machines come equipped with automated controls, enabling real-time monitoring and adjustments, which reduces manual intervention and improves precision.

- Modular Designs: Some sieving machines are built with modular components, allowing easy adjustments to mesh sizes and screen configurations based on changing needs.

- Noise Reduction Technologies: Recent designs incorporate noise-dampening materials and advanced vibration controls to minimize noise pollution, an essential feature for plants located in residential areas.

- Energy Efficiency: Newer machines are designed to consume less energy, which benefits companies aiming to reduce operational costs and environmental impact.

Key Considerations When Choosing a Sieving Machine

Selecting the right sieving machine requires consideration of various factors, including:

- Nature of Material: Different machines are better suited for dry, wet, coarse, or fine materials. Identifying the properties of the material helps narrow down suitable options.

- Production Volume: For high-volume applications, robust and high-throughput sieving machines are ideal. Small-scale operations may benefit more from compact, mobile sieving units.

- Compliance with Industry Standards: Ensure that the machine meets industry standards, especially if operating in regulated sectors like food or pharmaceuticals.

- Cost and ROI: Investing in a sieving machine can be significant, so calculating the potential return on investment is essential, taking into account factors like reduced waste and increased throughput.

Conclusion

Industrial sieving machines are essential tools that support quality control, enhance efficiency, and contribute to cost savings across various sectors. With a wide range of options available, companies can select a sieving machine tailored to their unique needs, whether it’s for filtering food particles, ensuring pharmaceutical cleanliness, or segregating mined materials. By understanding their specific requirements and choosing the right machine, industries can optimize production processes, meet regulatory demands, and maintain high-quality standards. As technology advances, sieving machines are only set to become more efficient, automated, and environmentally friendly, paving the way for enhanced productivity across the industrial landscape.